RADAN Doubles Output for Aerospace Engineer

The world’s most powerful sheet metal CAD/CAM software makes a continuing impact on an aerospace company’s bottom line, by halving the time to set up machining programs for its lasers and turret punches.

Kevin Travis (pictured right), CAD/CAM Engineer with Swift-Cor Aerospace, says RADAN also provides optimum material yield and minimum waste on cutting aluminium, stainless steel and titanium components for commercial jets and military aircraft, while giving him the confidence that every part will be completely accurate.

“Although our machines’ factory stated capabilities are + or – .005 of an inch, driving them with RADAN increases that accuracy to + or – .003 of an inch. Our machines can achieve accuracy beyond what they were designed for.”

He says the software streamlines the manufacturing service they offer to the aerospace industry, making it faster, smoother and more accurate. “RADAN is vital to Swift-Cor, and will be an integral part of our manufacturing process as long as I’m sitting in this chair.”

Generally most aerospace components are presented to Swift-Cor as Catia files which can be unfolded in Catia V5.20 before importing into RADAN. But there are times when they come as IGES, STEP of DXF files which are imported into RADAN for unfolding. “RADAN’s accuracy in flattening parts is excellent,” he says. “I’ve been regulating flats in this way since 1995.”

While many orders are ‘one-offs’ Swift-Cor does retain dedicated programs for single parts, already nested, which are used for repeat business. “I simply print the set-up sheet and attach it to the work order because it’s already been proven. It takes about 40 seconds to attach a program to that part, as opposed to around four minutes if I was doing it from scratch.”

Another important time-saver is the software’s ability to readily ‘tweak’ something without having to recreate the wheel every time. He says once he has a proven entity it can easily be amended. “I can pull an individual symbol out of a nest and draw up a new part: I can open a single part nest which I may want to make bigger and change the blank size, and it automatically updates everything. It’s so easy to make and track revisions in the drawings and the part symbols.”

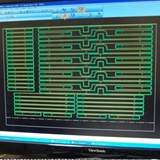

As Kevin Travis can often spend all day creating nests (pictured above), the flexibility, accuracy and material optimization provided by RADAN’s powerful nesting capabilities are particularly valuable. “It’s actually invaluable to me, allowing me to add parts, subtract parts, make the skeleton wider or closer, and get the best yield while substantially reducing material wastage. My output is double what it would be without RADAN.” And he says, that, in turn, helps Swift-Cor provide a fast turnaround time to customers, giving a positive impact on the company’s bottom line.

Most of the parts he works on are programmed by Radpunch for machining on Nisshinbo and Amada turret punches, while some components are laser cut on Bystronics driven by Radprofile. But whichever cutting technology is used, the parts are nested by the powerful Radnest module that analyses their true shape, dramatically increasing sheet utilization and delivering substantial cost savings on the expensive sheet metal.

A number of shop floor operatives have a working knowledge of RADAN. “Even though they haven’t been trained on it they easily picked it up with a little guidance, and can view parts to query features, check angles and make dimensional queries.” Some of the machine operators even undertake simple programming when something needs doing urgently and Kevin Travis is not there. “They may have picked up a slug in a punch, or they may need to make another part or two to complete an order. They go in, repeat the symbol, and input the blank size.”